How Welding Inspection Madison Ensures Quality and Safety in Fabrication

Wiki Article

Just How Effective Welding Assessment Enhances Structural Stability and Longevity

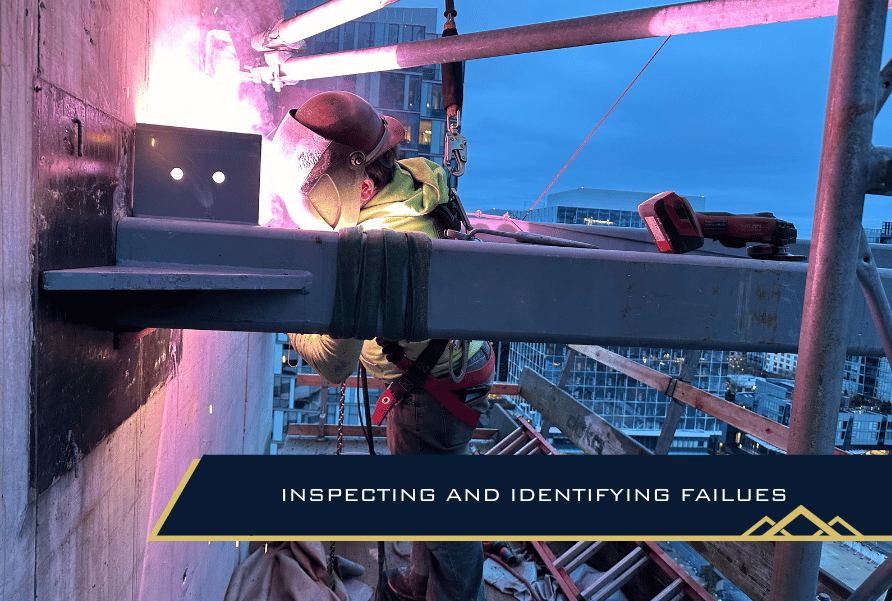

In the world of building and construction and design, the significance of welding evaluation can not be overstated, as it plays a pivotal duty in making sure structural integrity and expanding the life expectancy of projects. Sign up with the expedition of how effective welding examinations can change potential susceptabilities into strengths, adding to the enduring success of building and constructions.Relevance of Welding Assessment

Ensuring the structural integrity and security of welded buildings requireds strenuous welding examination processes. Welding inspection serves as an important secure in the building and construction and production sectors, where the toughness and durability of joints significantly impact the overall performance of structures.Along with security, welding examination plays an essential function in high quality assurance. By sticking to fixed requirements, examinations determine the consistency of welds, guaranteeing that each meets the desired toughness and visual demands. This consistency is vital not only for safety and security but also for preserving the credibility and reliability of manufacturers and makers. Furthermore, regulatory conformity is a substantial vehicle driver of welding evaluation methods. Market standards and codes, such as those from the American Welding Culture (AWS) or the International Organization for Standardization (ISO), demand adherence to stringent standards, underscoring the importance of examinations in satisfying these lawful and expert commitments.

Key Assessment Methods

Ultrasonic Checking (UT) uses high-frequency acoustic waves to detect subsurface imperfections, providing precise details regarding weld integrity without triggering any damages. Radiographic Testing (RT), entailing X-rays or gamma rays, offers a thorough picture of the weld's internal structure, revealing concealed imperfections. Magnetic Bit Testing (MPT) is one more non-destructive method, especially effective for detecting surface area and near-surface gaps in ferromagnetic products.

Penetrant Testing (PT) entails the application of a liquid color to reveal surface-breaking problems, supplying a affordable and uncomplicated solution for non-porous materials. Each method has its details applications, strengths, and constraints, and frequently a mix of methods is utilized to accomplish comprehensive assessment outcomes. Proficiency of these strategies enhances the dependability and durability of welded structures, straightening with safety and security and performance expectations.

Identifying Common Flaws

Porosity, defined by gas pockets within the weld, lowers the weld's strength and toughness. It often results from pollutants or inappropriate shielding gas. Cracks, which can happen throughout or after welding, posture significant dangers as a result of their possible to circulate under stress. They typically emerge from too much stress, rapid cooling, or incorrect weld style.

Insufficient blend, where the weld steel stops working to bond entirely with the base product, weakens the structural stability, resulting in weak joints. This problem normally comes from inadequate warm input or incorrect welding strategy. Slag additions occur when non-metallic materials are trapped in the weld, compromising its toughness and high quality. These are typically a result of inadequate cleansing between weld passes or improper change usage.

Identifying these defects via careful assessment methods, such as aesthetic evaluation, ultrasonic screening, or radiography, is critical. Resolving these issues ensures weld top quality, inevitably supporting the architectural stability and security of the developed setting.

Enhancing Structural Efficiency

Recognizing the relevance of determining typical weld problems naturally brings about discovering techniques for improving structural efficiency. The foundational method for improving efficiency involves employing innovative welding methods and materials that mitigate issue incident. Utilizing high-grade filler products and guaranteeing appropriate heat control can considerably lower issues such as porosity and cracking, therefore enhancing the weld's honesty.Including state-of-the-art welding technologies, such as laser welding and rubbing mix welding, additional magnifies structural strength. These methods supply remarkable precision and lowered thermal distortion, directly influencing the toughness and strength of the bonded structures. Taking on automated welding systems can make certain constant and repeatable weld quality, lessening human mistake.

In addition, executing strenuous pre-weld and post-weld treatments is important. Correct joint style, surface preparation, and stress-relieving processes add to optimal weld efficiency. Conducting complete pre-weld inspections allows for very early detection of prospective concerns, see post facilitating timely corrections before they jeopardize the framework.

Lasting Advantages of Evaluation

Through vigilant evaluation practices, the lasting benefits to structural honesty come to be significantly apparent. Detailed and regular welding assessments play a critical duty in preventing architectural failures by determining incongruities and flaws early in the building and construction procedure.

In addition, regular inspections add to maintaining compliance with market criteria and guidelines, thereby preventing lawful and economic effects. This adherence to quality assurance not only improves the reliability of the structure however likewise promotes trust fund among stakeholders, consisting of customers, designers, and regulatory bodies. The comprehensive documents of inspection outcomes functions as an important source for future upkeep and fixing initiatives, promoting educated decision-making.

Furthermore, reliable examination techniques sustain advancement by incorporating sophisticated innovations such as non-destructive testing and digital imaging, which can boost accuracy and effectiveness. This technological integration further emphasizes the commitment to excellence in architectural honesty. Eventually, investing in thorough welding examinations is a sensible technique that yields significant long-term benefits, guarding both the physical and economic financial investment in facilities projects.

Verdict

Efficient welding evaluation plays a crucial function in improving architectural stability and durability by recognizing defects early in the construction procedure. Using methods such as visual assessment, ultrasonic testing, and radiographic screening guarantees the discovery of issues like fractures and porosity that compromise weld stamina. Rigorous assessments ensure compliance with sector standards, consequently prolonging the life expectancy of frameworks, reducing pricey repairs, and promoting stakeholder trust fund in the integrity and security of bonded building and constructions.

In the realm of hop over to these guys building and engineering, the relevance of welding inspection can not be overemphasized, as it plays a crucial role in making certain structural integrity and prolonging the life expectancy of jobs.Ensuring the architectural honesty and security of welded building and constructions requireds rigorous welding inspection processes.Building upon the importance of welding assessment in guarding architectural honesty, recognizing the key inspection techniques becomes necessary for reliable execution. Reliable welding assessment includes a variety of techniques developed to assess weld quality, ensuring conformity with rigorous design requirements - Welding Inspection Madison.Effective welding inspection plays a vital role in boosting architectural stability and longevity by identifying go now issues early in the building and construction procedure

Report this wiki page